Advanced data science and AI are no longer futuristic concepts in logistics; they are reshaping the game, paving the way for faster, smarter, cheaper, and more sustainable inventory management. Mastering these transformative tools can be the defining difference between success and stagnation in the cutthroat retail arena.

“Data science is undeniably the future of optimized transportation and logistics,” says Evan Rock, VP of Sales & Marketing at Quiet, a wholly-owned subsidiary of American Eagle Outfitters Inc. (NYSE: AEO). “Market leaders like AEO are already leveraging it to surge ahead, slashing delivery miles by over 50% and saving millions along the way.”

But what about your business? How can you harness this technological wave without the massive resources of a market leader like AEO?

This whitepaper unveils the four-step approach to intelligent inventory management pioneered by Quiet. We’ll offer a glimpse into our data science applications, providing you with unprecedented insights into inventory, orders, and deliveries. These are processes you can build or gain access to by joining our network, leading to potential cost reductions of up to 20%, boosting customer satisfaction and loyalty, and contributing to decarbonization efforts.

Where smart people meet smart technology

Data scientists have long been among the most coveted professionals in the United States. Their unique and evolving skill set, which includes collecting, analyzing and interpreting data to drive decision-making, is only becoming more critical as technology advances and more organizations lean into the capabilities that it brings.

"Data science is undeniably the future of optimized transportation and logistics."

Evan Rock, VP of Sales & Marketing

at Quiet

AI in Retail: A Trend Rapidly Picking Up Steam

The global market for the use of Artificial Intelligence (AI) in retail was valued at 4.84 billion U.S. dollars in 2021. Over the following eight-year period, the market for AI in retail is estimated to grow almost exponentially, reaching 31.18 billion U.S. dollars by 2028.

Since the 1960s, retailers have harnessed the power of data science in supply chain management. Pioneering tools like time-series analysis and regression have been instrumental in forecasting demand and optimizing inventory levels within the logistics sector.

Today, data scientists have more tools than ever at their disposal to reshape the supply chain to change the way supply chain teams forecast demand, optimize routing, manage inventory, automate warehouse processes, maximize supply chain visibility, manage risk, and cultivate supplier relationships.

Some of the best and brightest of these professionals are part of the Quiet team.

In fact, Quiet houses the biggest data science team in retail logistics, led by Gabriella Runnels, a rising star in the field. Runnels, a graduate of Georgia Tech’s Master of Science in Analytics program and recipient of the MSA Rising Star Award, and her team provide the expertise that fuels the company’s innovative solutions.

“Our people combine a deep knowledge of retail and omnichannel fulfillment with cutting-edge data science capabilities to harness the power of AI and other emerging technologies to boldly forge new frontiers in intelligent logistics and inventory management,” says Runnels.

“In a world where customer loyalty is the oxygen of retail success, we are hard at work in the background helping clients gain an Edge.”

How our advanced data science elevates your logistics

Predictive Inventory Optimization

- Product Assortment: Our intelligent algorithms analyze customer demand patterns and historical data to determine the optimal product mix for each fulfillment center, ensuring you always have the right inventory at the right place.

- Dynamic Carton Routing: Real-time data insights guide the routing of incoming shipments to their ideal destinations, minimizing transportation costs and maximizing efficiency.

- Inventory Rebalancing: We proactively manage your inventory levels across the network, ensuring optimal stock at each node to fulfill orders quickly and prevent stockouts.

- Inventory Intelligence Layer: Gain real-time visibility into your inventory health and leverage actionable insights to optimize margin, reduce waste, and make data-driven decisions.

Beyond Inventory

- Network Optimization: Our data science models analyze various factors like order volume, location, and transportation costs to strategically design your fulfillment network, ensuring optimal efficiency and cost-effectiveness.

- Dynamix Carrier Selection: We leverage real-time data and machine learning to select the most suitable last-mile carrier for each delivery, considering factors like cost, speed, and customer preferences.

- Demand Forecasting: Our advanced algorithms analyze historical sales data and market trends to predict future demand with remarkable accuracy, enabling you to optimize inventory levels and proactively prepare for peak seasons.

- Pick Path Optimization: Our AI-powered app maps fulfillment requests and SLAs to create streamline pick paths, boosting productivity and reducing fulfillment times.

- Storage Optimization: Our data-driven app optimizes an individual warehouse layout, ensuring active items are easily accessible while minimizing inactive inventory.

4 Apps to Create Certainty in Uncertain Times

Quiet has developed a suite of four applications that work together to take your inventory management capabilities to new levels. The first two apps, the Forecasting App and Assortment App, are focused on planning, while Apps 3 and 4, the Dynamic Carton Routing App and Transfer App, turn the focus to operations and execution. Runnels calls these the “rebalancing apps” because they can iron out any wrinkles in the system to ensure optimization across the network.

“Shipping and delivery costs remain one of the highest costs of online business. So the intention of our data science interventions is really simple: To decrease those delivery costs by having the inventory close to the customer at the right time in the right quantity. We get this right by making sure we are getting the right signals from the right sources at every step of the journey to guide our decision-making,” she says.

App 1: Forecasting

Forecasting is hard. It always has been, and with shifting consumer demand fueled by mercurial social media influencers—it’s not getting any easier. Research from the Harvard Business Review highlights that over the pandemic years, 98% of executives reported that bad forecasts undermined their business performance, leading to material shortages, missed revenue opportunities and decreased customer satisfaction and profitability.

Runnels shares that forecasting in uncertain times requires systems that can handle continuous sensing of demand and supply and then be able to link that ebb and flow to execution.

To make this a reality, Quiet’s forecasting app draws on a variety of data, including customer order histories, macroeconomic data about retail or financial trends and, in some cases, weather data, to provide a weekly forecast for future sales and locations. The App goes further than most forecasting tools on the market because it uses several machine-learning algorithms to improve its accuracy over time enabling it also to choose the best-fit prediction for each product.

“The system also compares how forecasts performed against actual sales and orders and if we detect that a forecast is not performing as accurately as we expected, we can review it to see if we can improve the model or address whatever the business issue is that caused that,” comments Runnels.

“The really cool thing is that even if a particular product doesn’t actually have any sales history – say it is a new product – we can associate it with other similar products and still run a fairly accurate sales forecast to get the product up and running.”

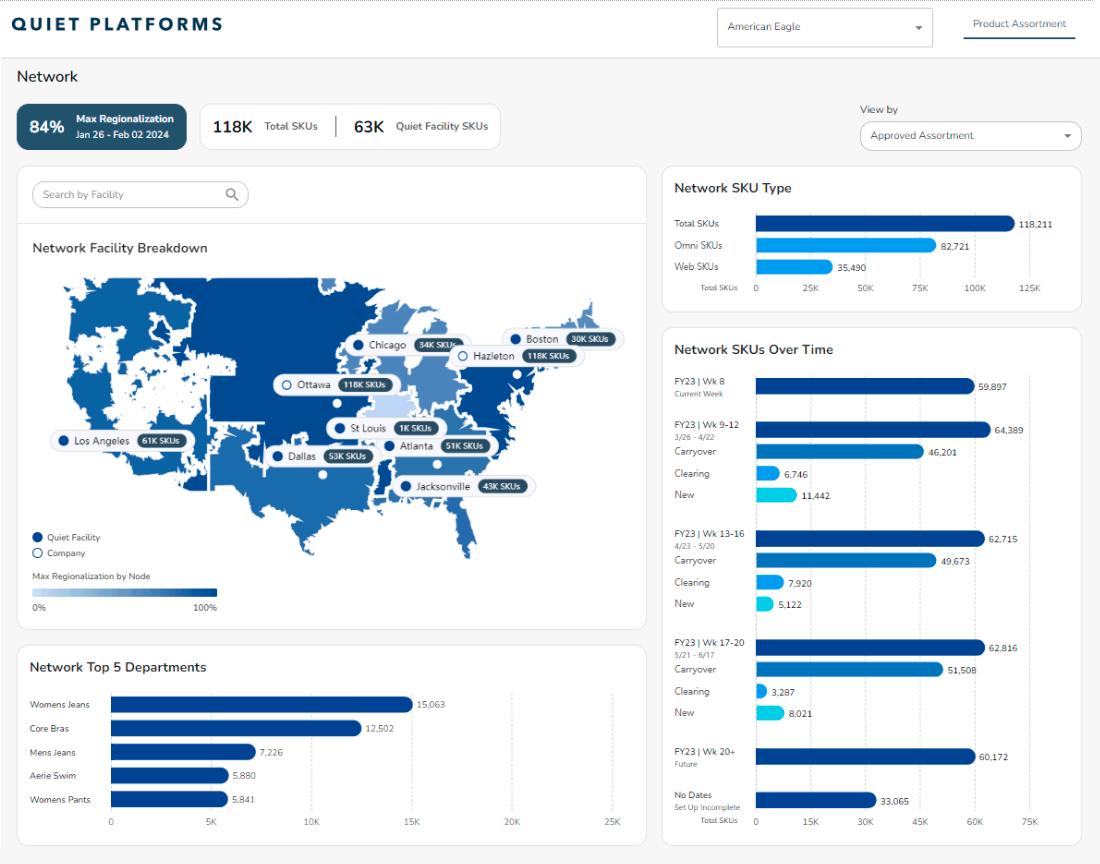

App 2: Product Assortment

Forecasting in isolation can only take you so far, you also need to have the ability to plan and place inventory. Our second tool, the Quiet Assortment App, is designed to make sure that inventory is optimally placed and maintained at each node in the system. This is particularly useful for regional retailers that have limited inventory or that don’t need to store their full assortment in all locations.

The Assortment App can minimize split shipments by stocking products that are likely to be ordered at the same time in the same location. The App is driven by an affinity model, which analyzes product order histories and decides which products are more likely to be ordered together in the same transaction so that you can ensure those orders are not split. This, in turn, helps to streamline the overall inventory management process.

Runnels explains, “The affinity model crunches the data from product order histories to determine that a customer who buys a particular football jersey is likely to buy a particular hat or similar. The Assortment App then uses this information to ensure that the two items are stocked together in the same location. Using these tools, we were able to slash split shipments by 0.4 shipments per order (1.5+ average to 1.11 average). This is massive, as every 0.01 decrease translates to about $1 million saved for one of our larger customers!”

The App is particularly effective at enabling retailers to respond to regional and seasonal variations. It ensures, for example, that there are more Red Sox items close to Boston than San Francisco but more 49ers items close to San Francisco than Boston. When it comes to seasonality, the Assortment App ensures that locations in the south stock summer clothes towards the start of the year while warehouses in the north stock winter clothes.

"Shipping and delivery costs remain one of the highest costs of online business."

Gabriella Runnels, Principal Data Scientist at Quiet

Our Product Assortment app analyzies customer demand patterns and historical data to determine the optimal product mix for each fulfillment center, ensuring you always have the right inventory at the right place.

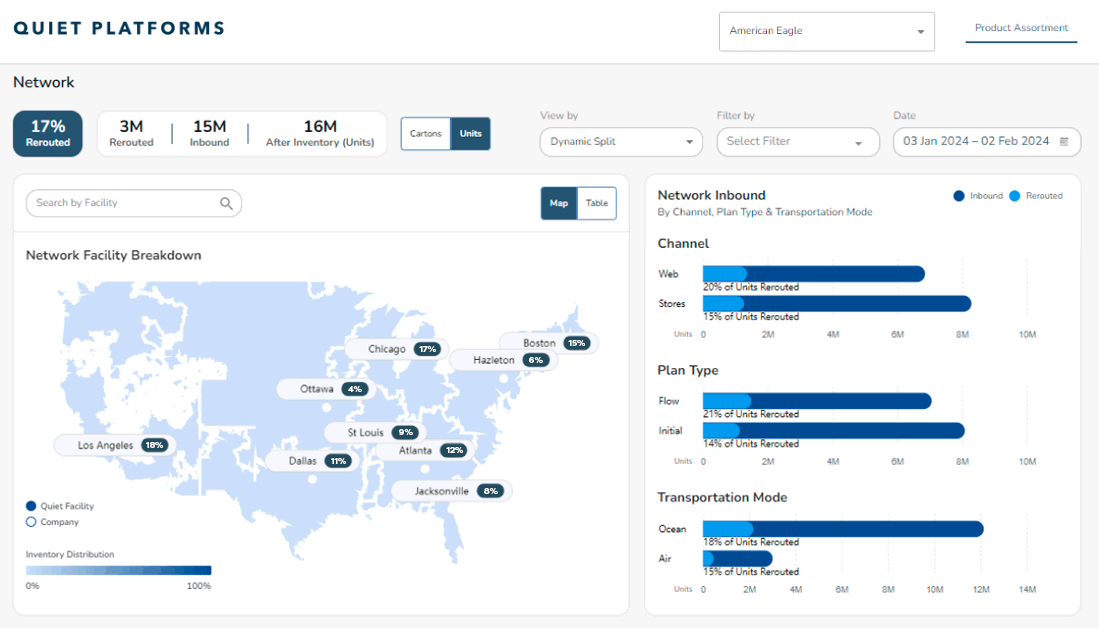

App 3: Dynamic Carton Routing

For many retailers, receiving new merchandise from manufacturers is a multi-step process. Initial shipments often land at one port, and need to be stored and rerouted to several warehouses in order to optimize customer delivery costs downstream. Quiet tackles this challenge with our Dynamic Carton Routing App.

This innovative app utilizes a powerful algorithm to intelligently route cartons to the warehouses closest to their final destinations. Its key feature? Real-time barcode reassignment at the port. By considering current inventory levels and upcoming demand, the app dynamically optimizes distribution based on our network’s immediate needs.

Our Dynamic Carton app offers real-time data insights to guide the routing of incoming shipments from manufacturing to their ideal destinations, minimizing transportation costs and maximizing efficiency.

The benefits manifest as more precise inventory management, faster adaptation to shifting demand, and more efficient deployment of resources—which translates to dollars saved. For Quiet, we use an average estimate of $0.10 per unit as a cost for a transfer. So for each unit we send directly to the correct node, rather than having to replenish via a transfer, we can save about ten cents.

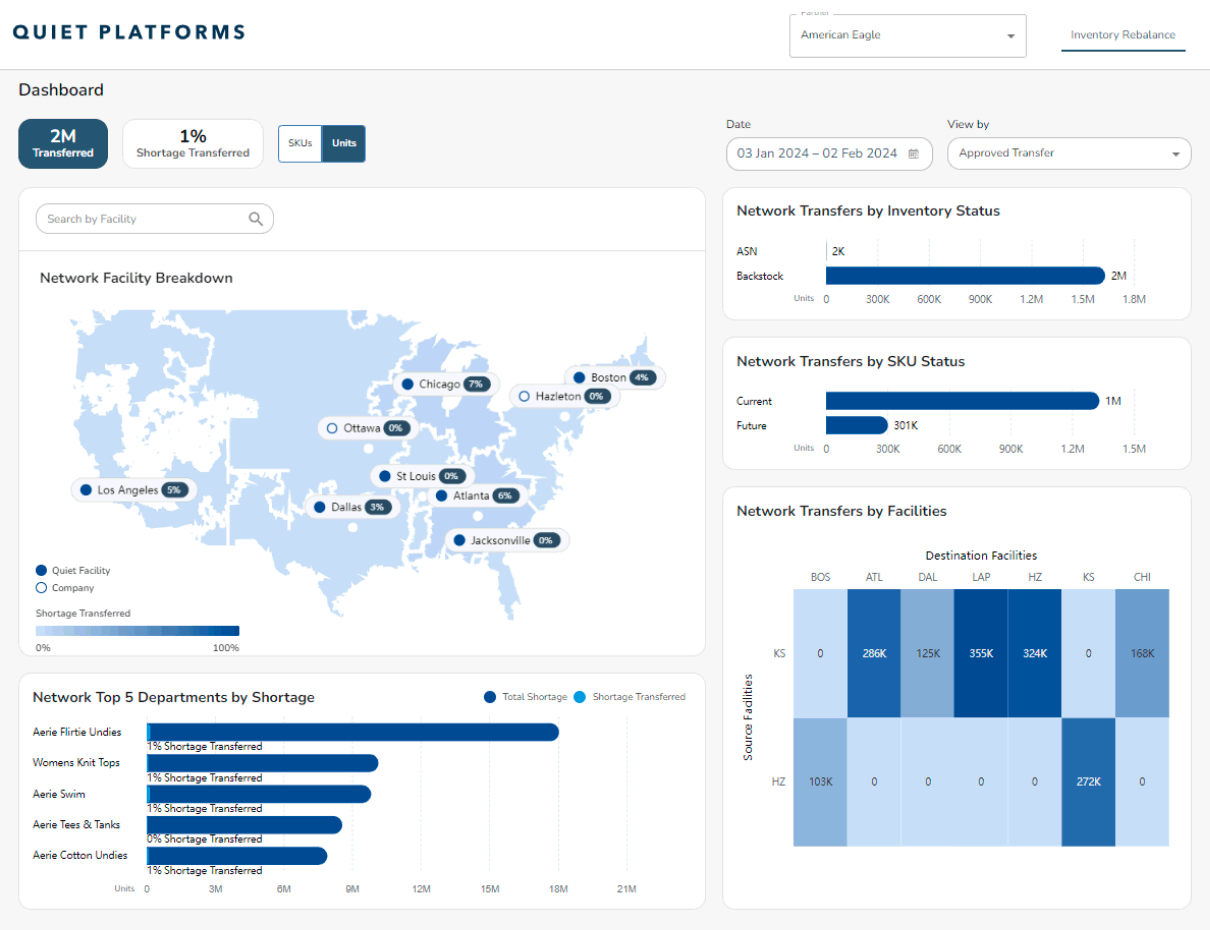

Our Inventory Rebalancing app proactively manages inventory levels across our network, ensuring optimal stock at each node to fulfill orders quickly and prevent stockouts.

App 4: Inventory Rebalance

The last key piece in Quiet’s orchestration of inventory management lies in its ability to use technology to optimize the transfer of inventory between warehouses. “There are all sorts of reasons why you might need to do this: to optimize storage capacity, to move stock closer to a store where it is flying off the shelves, or to balance out supply in various nodes,” says Runnels.

“Quiet’s Transfer App uses our data science capabilities to monitor inventory health and provide inventory management teams with real-time insights that support the rapid and efficient transfer of inventory between warehouses to ensure that optimal inventory is maintained at each node. Among other benefits, this helps to prevent stock-outs, optimizes inventory use, reduces miles per package, and helps to build a more responsive and resilient supply chain.”

This app achieves its goal by analyzing demand forecasts to identify supply needs in each location. It then rebalances inventory based on a combination of factors, including storage costs, fulfillment costs, and potential shortage costs for each location.

For American Eagle Outfitters, with a one-week transfer lead time and weekly options for rebalancing, the app helps us make quick and informed decisions. For example, if we see Chicago only has two weeks of supply while Dallas has 20, the app suggests the optimal transfer quantity to ensure Chicago avoids stockouts while maintaining sufficient overall inventory. By continuously optimizing inventory transfers, we’ve achieved a remarkable 33% reduction in average miles per package, dropping from 825 to 550. This translates to a more efficient and cost-effective supply chain.

The future of retail is data-driven, and the possibilities are endless

The future is data-driven, not guesswork, and more and more retailers are taking the leap. Advanced data science and AI are reshaping the game, offering retailers like yourself the opportunity to unlock significant value through optimization, improved customer satisfaction, and a competitive edge.

Quiet has been at the forefront of this revolution, pioneering a holistic inventory management system powered by cutting-edge data science and AI. Our suite of four interconnected applications – Forecasting, Assortment, Dynamic Carton Routing, and Inventory Rebalance – work together seamlessly to optimize your entire inventory ecosystem. These pair with our other data-driven applications that optimize the whole supply chain, helping us to operate so efficiently, we can offer our services to help you save on average 20% of your logistics cost—and we can still make money.

The difference is powerful. Imagine:

- Reduced shipping and delivery costs by having the right inventory, in the right quantity, at the right location.

- Improved forecast accuracy through machine learning algorithms that adapt to ever-changing consumer demands.

- Minimized stockouts and split shipments thanks to intelligent inventory allocation and real-time data insights.

- Enhanced operational efficiency with streamlined processes and automated decision-making.

These are just some of the benefits that data-driven inventory management can deliver. By partnering with Quiet, you gain access to:

- A team of leading data scientists with deep expertise in retail and omnichannel fulfillment.

- Cutting-edge technology designed to solve your specific inventory challenges.

- Proven results like those achieved by American Eagle Outfitters, who slashed delivery miles by over 50% with our Dynamic Carton Routing app.

Don’t get left behind in the data revolution. Contact us today to learn how Quiet can help you unlock the full potential of your inventory management and empower your business for success in the data-driven future.

The future is data-driven, not guesswork, and more and more retailers are taking the leap.